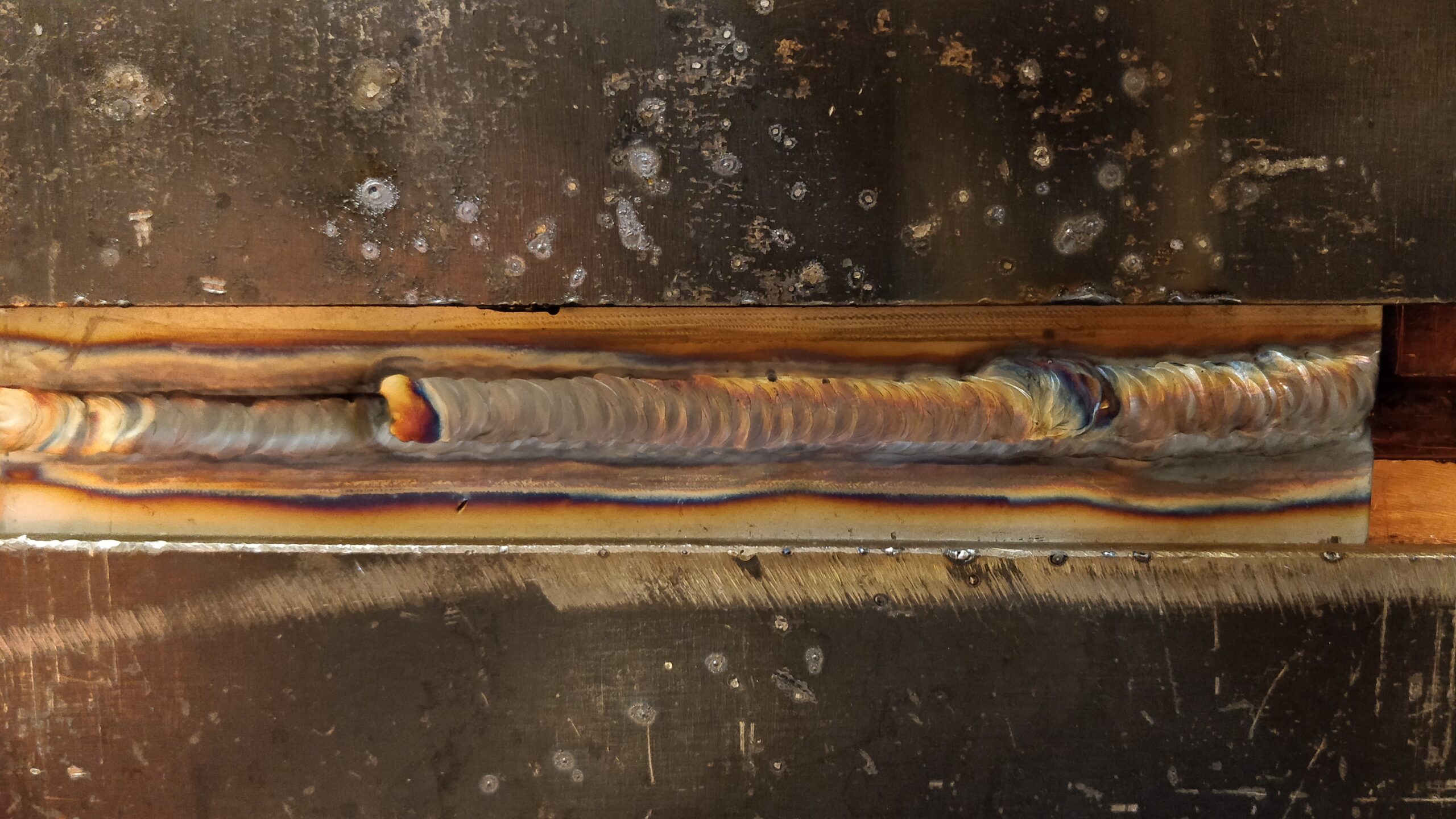

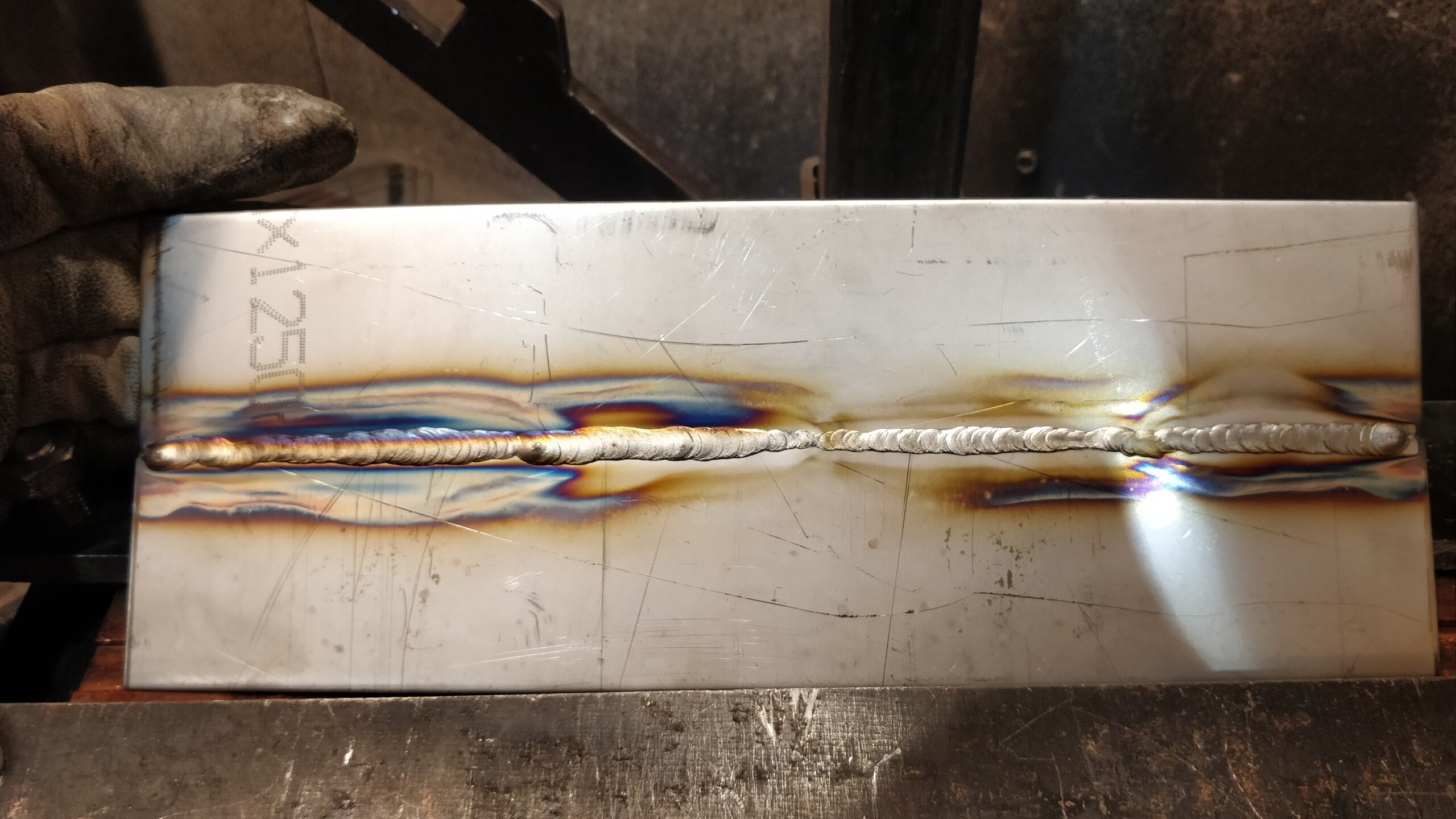

Initial training as welder included welding various material types. I showed some cases of aluminum welding. This post however has some examples of tests I took as basic welder (C-class tolerances) and other test/works I took for certification (B-class tolerances) on stainless steel (SS). If I knew SS was such a pain to master, I would choose aluminum. On the other hand, I do not choose the easy ways.

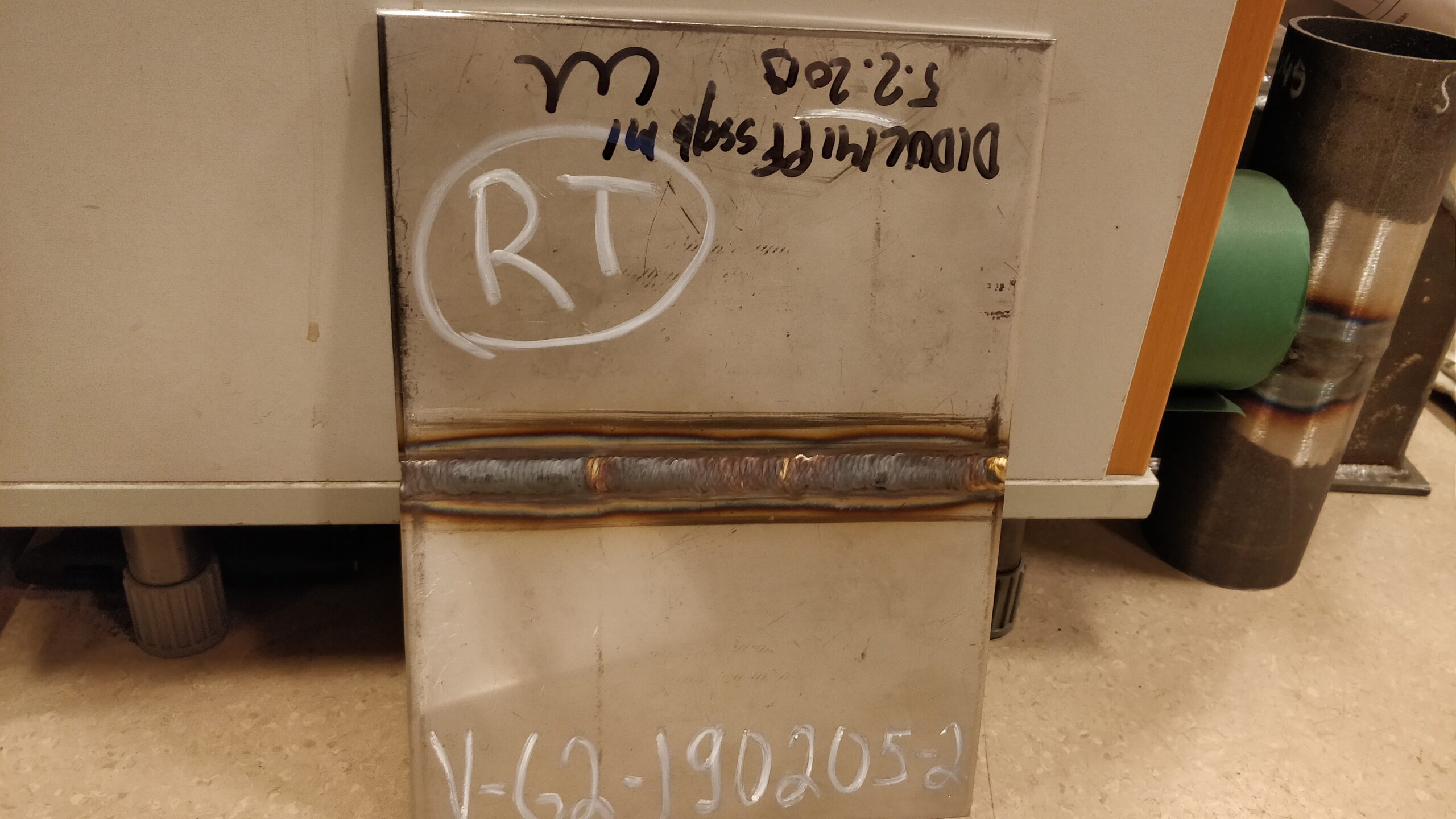

C-class welding

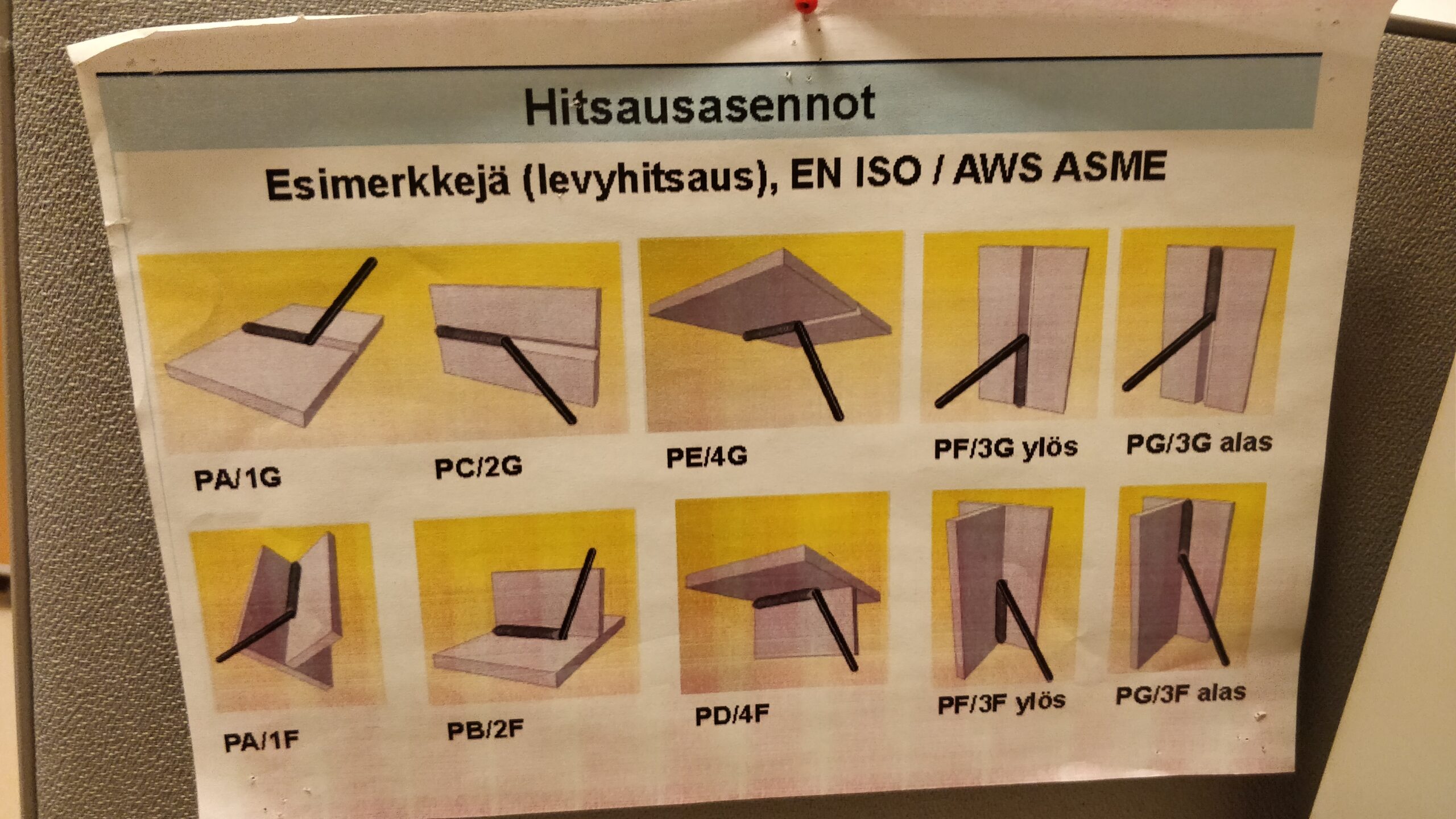

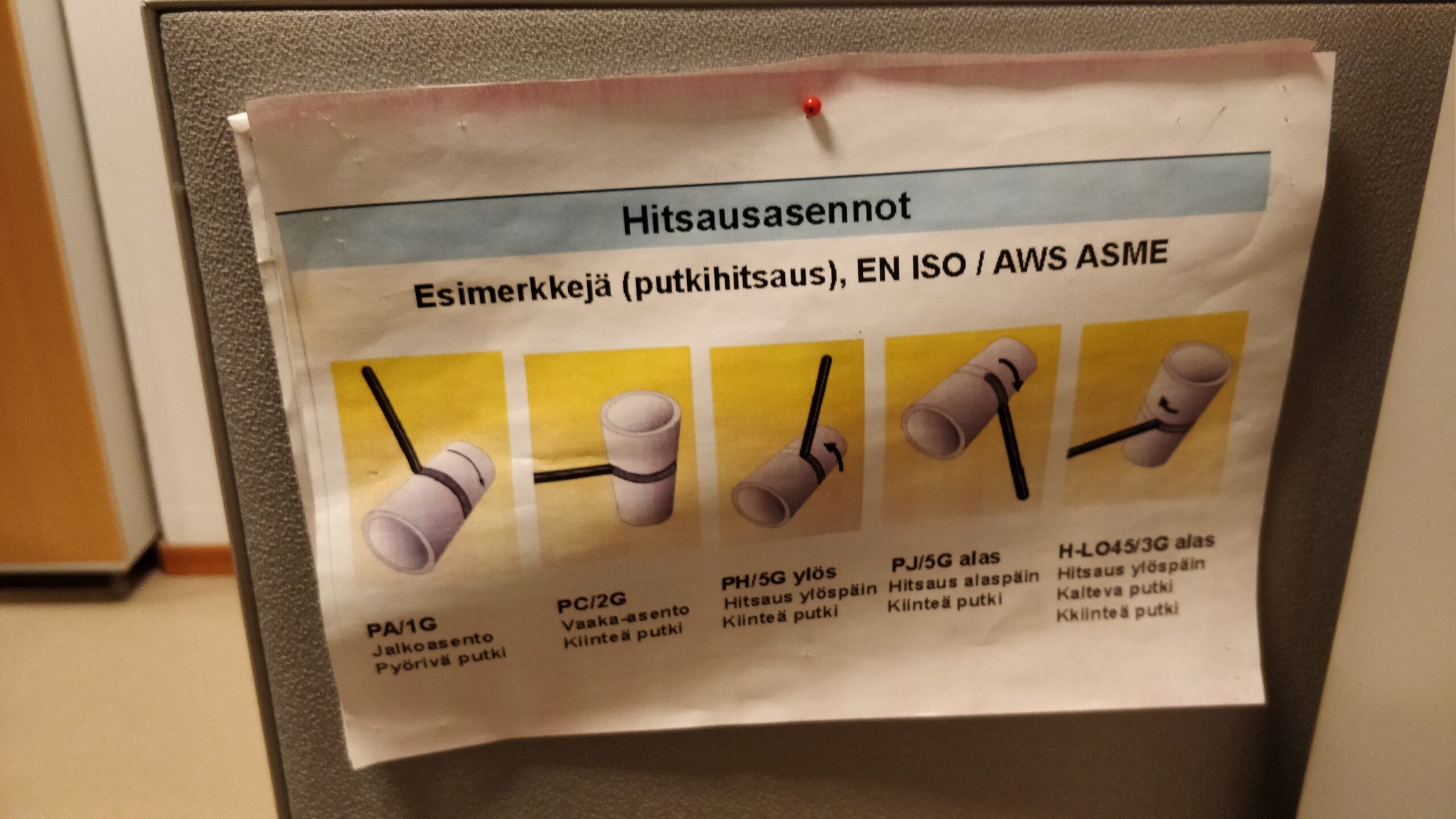

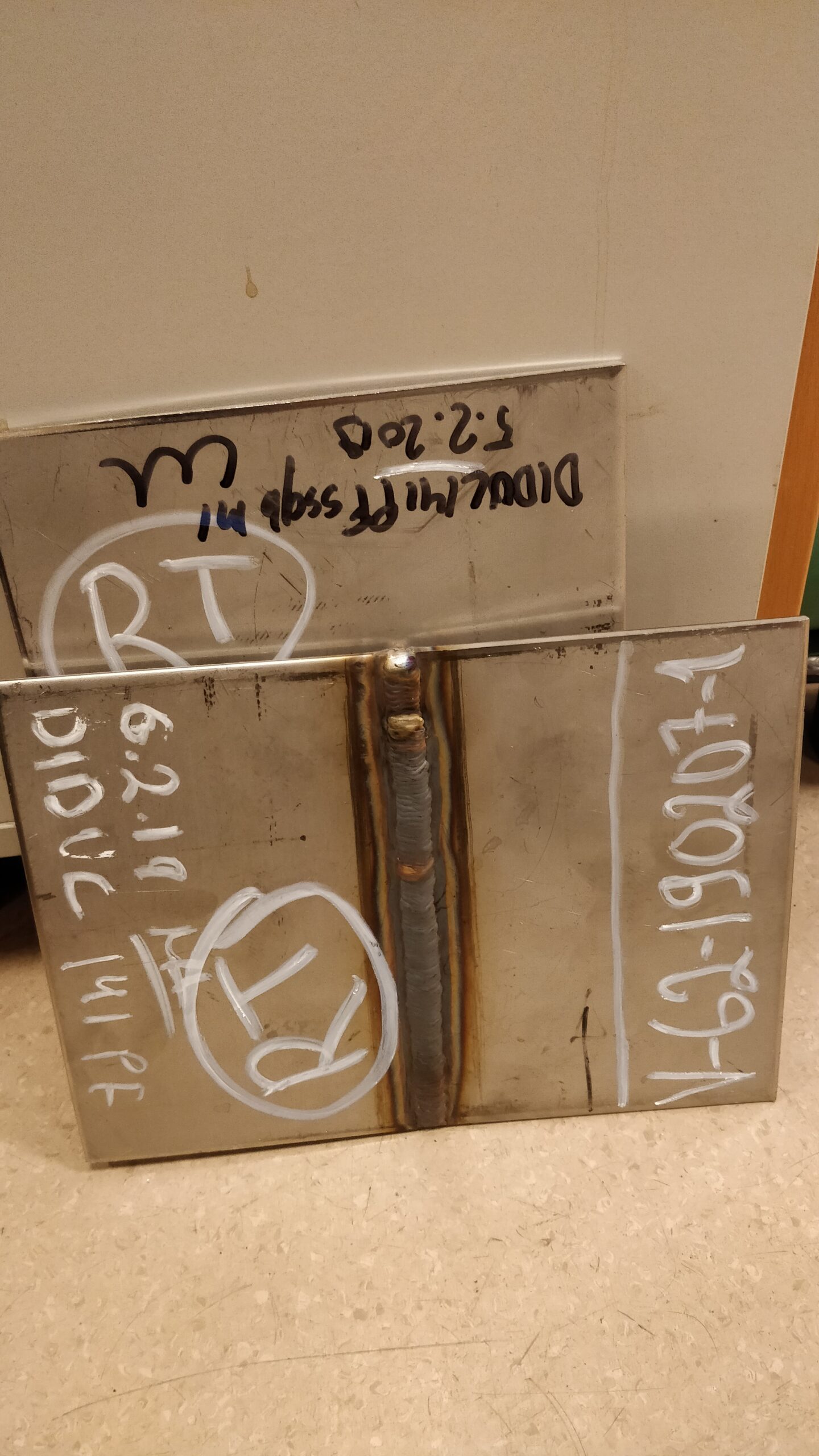

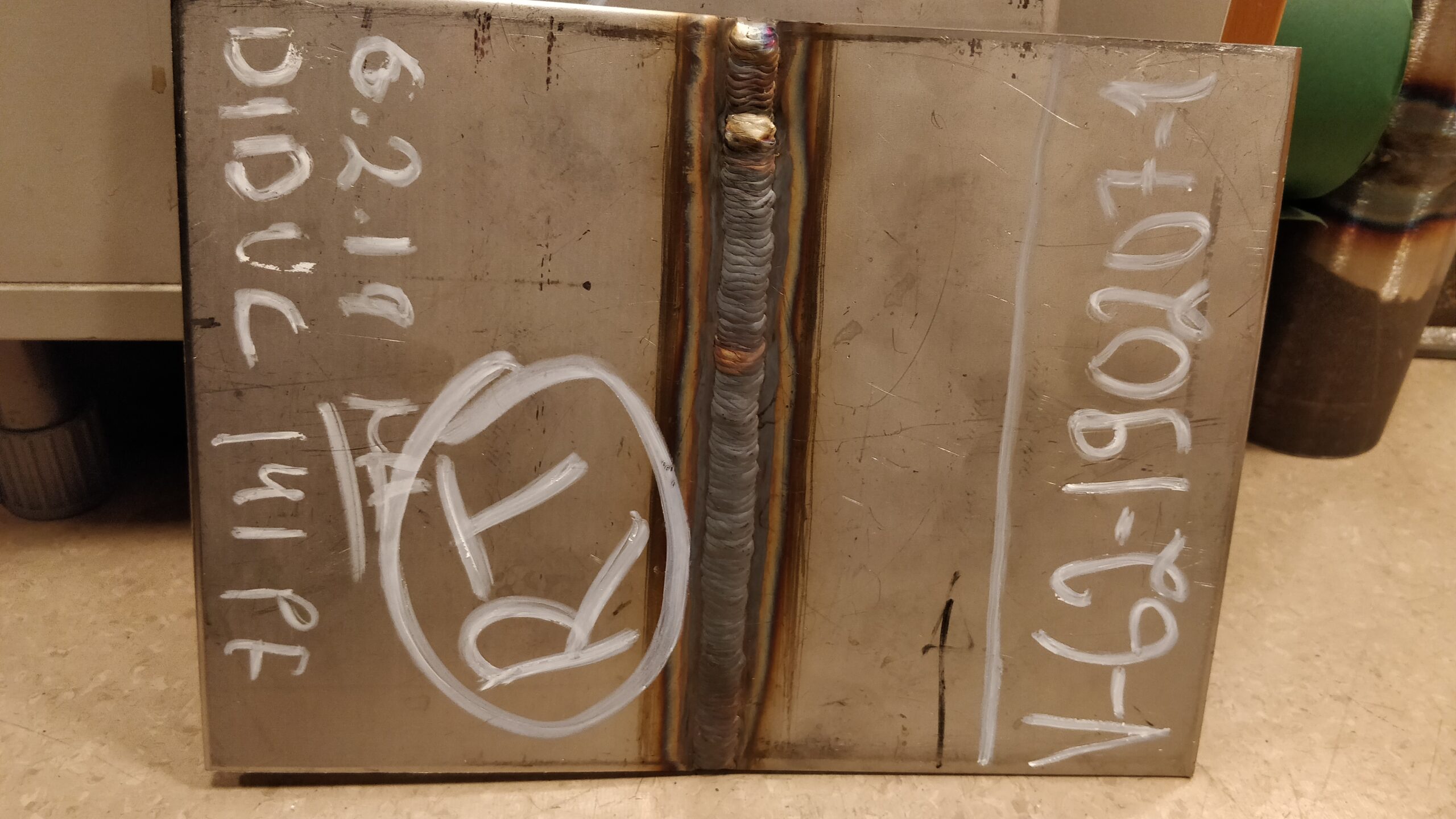

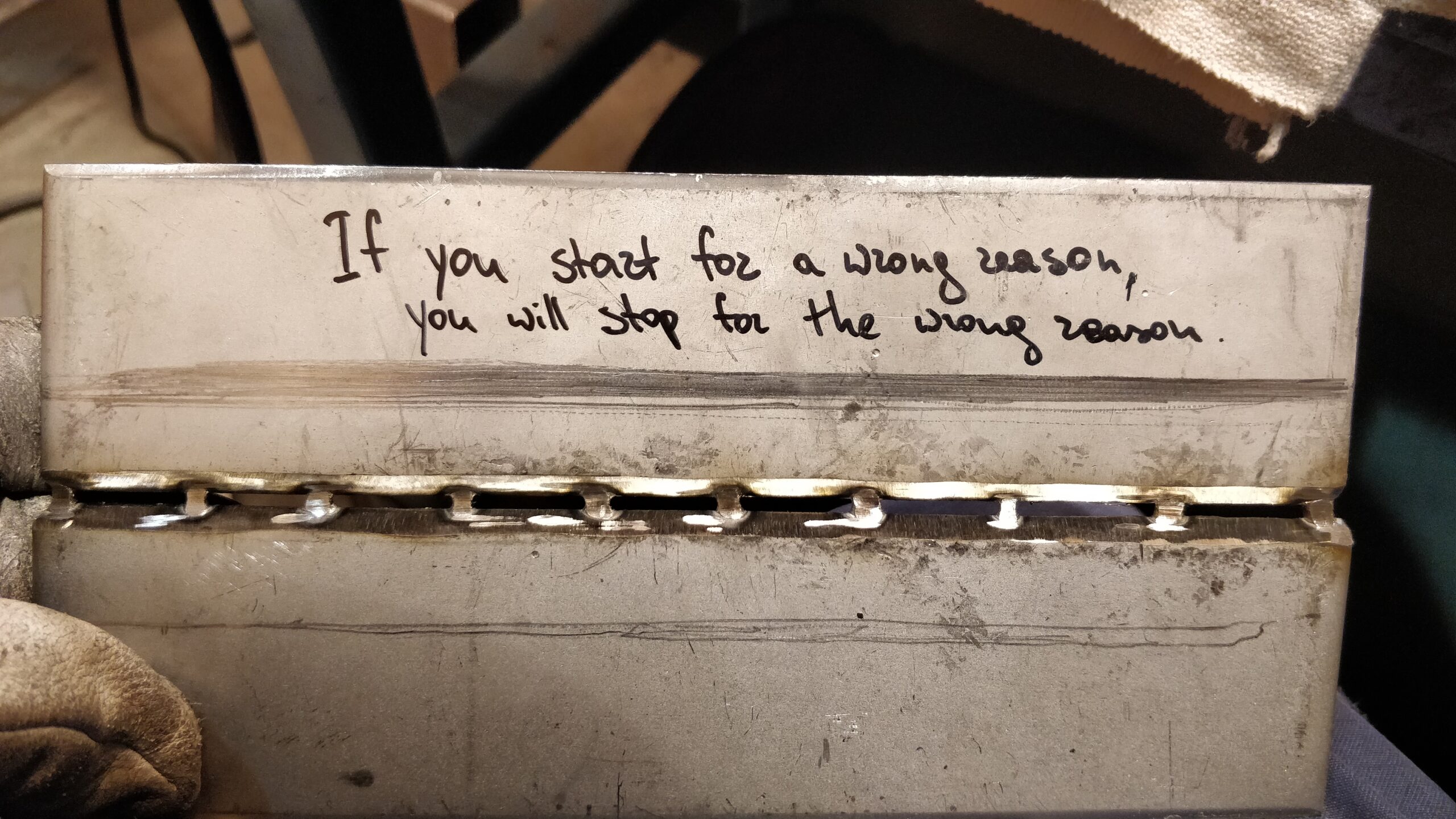

These are the test results of welding in PB and PF position on 3 mm thick SS plate.

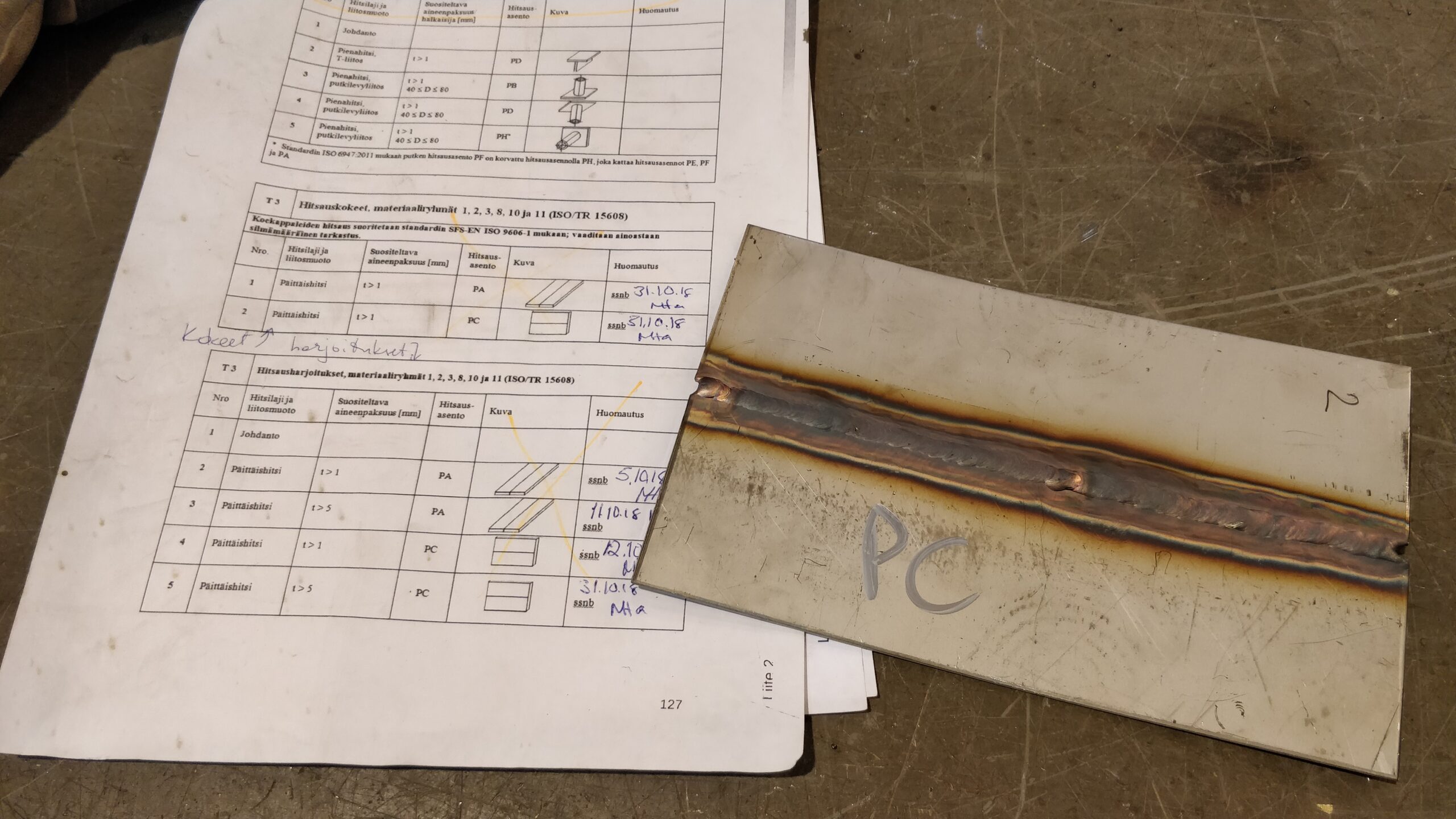

B-class

The tests were evaluated according to ISO 9606-1:2017 standard.

There are other photos of numerous attempts to master stainless steel. Frankly, welding SS is quite a challenge. My teachers were not good help in my studies. Their help expressed in the encouragement to try something different. I did. It took me as much time to pass the tests as much it took mastering both MMA and MAG welding together. I would love to have more experience with SS.

Message: “If you start for a wrong reason, you will stop for the wrong reason.”