The advantage of doing well in school was the possibility to try and practice various materials and welding processes. Here are some of the projects that I did in school. Some of the projects required cutting the materials on the machine. Others required designing parts in AutoCAD Inventor according to the verbal descriptions or pen&paper drafts, the 3D-design then was changed the .step format suitable for cutting machine reading, placement of the parts on the sheet of material and actual water-jet cutting.

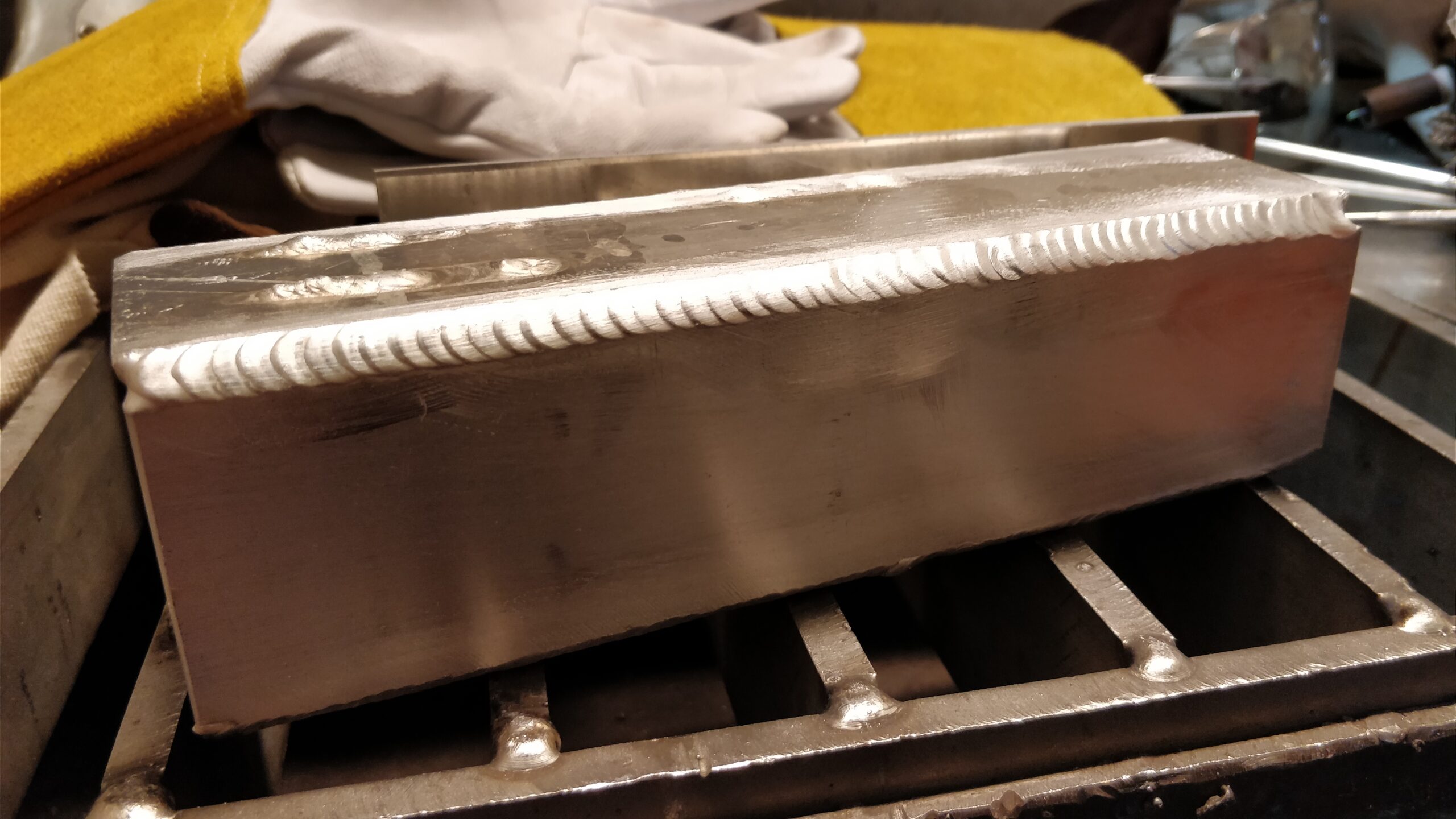

MIG 131

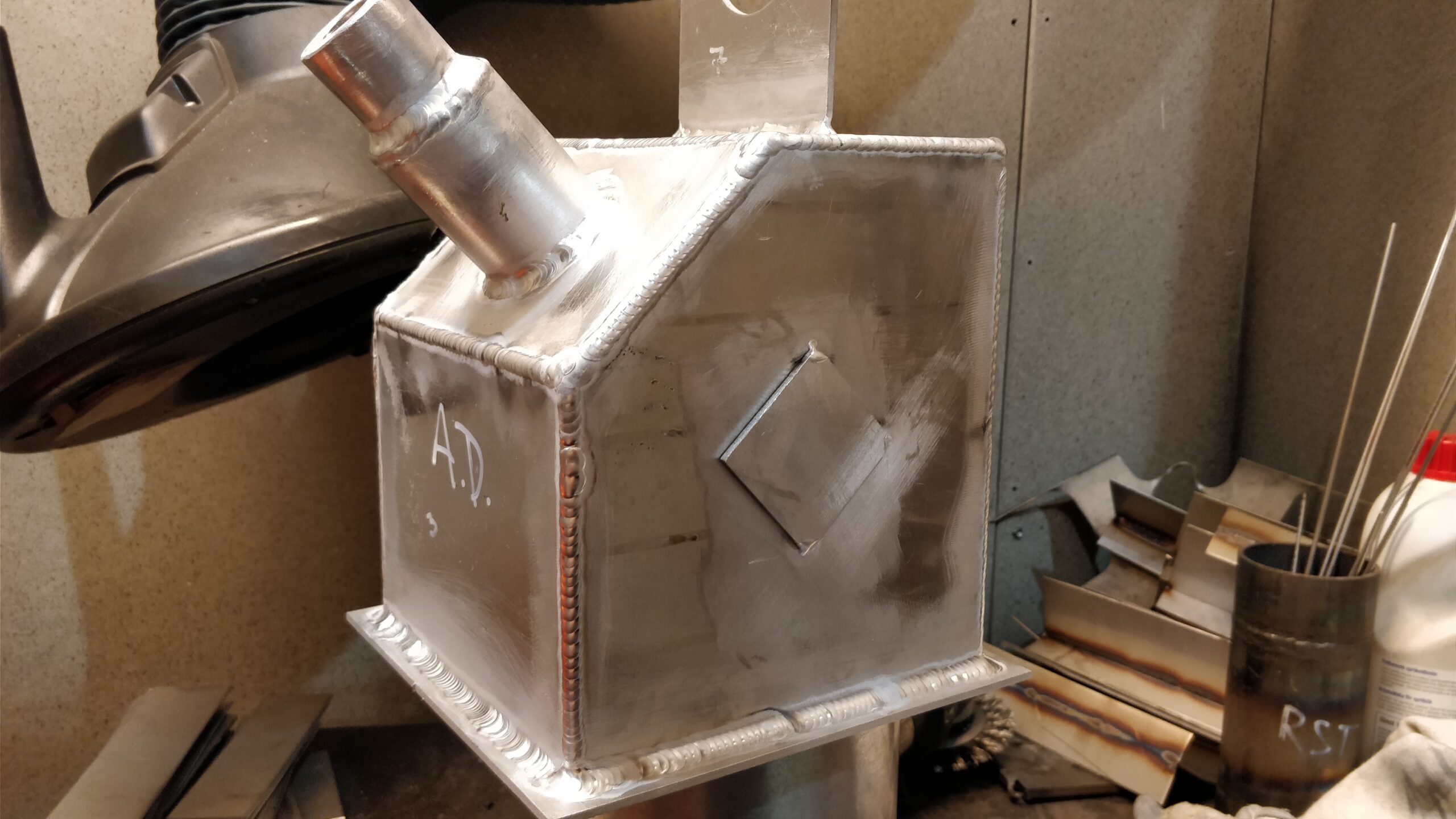

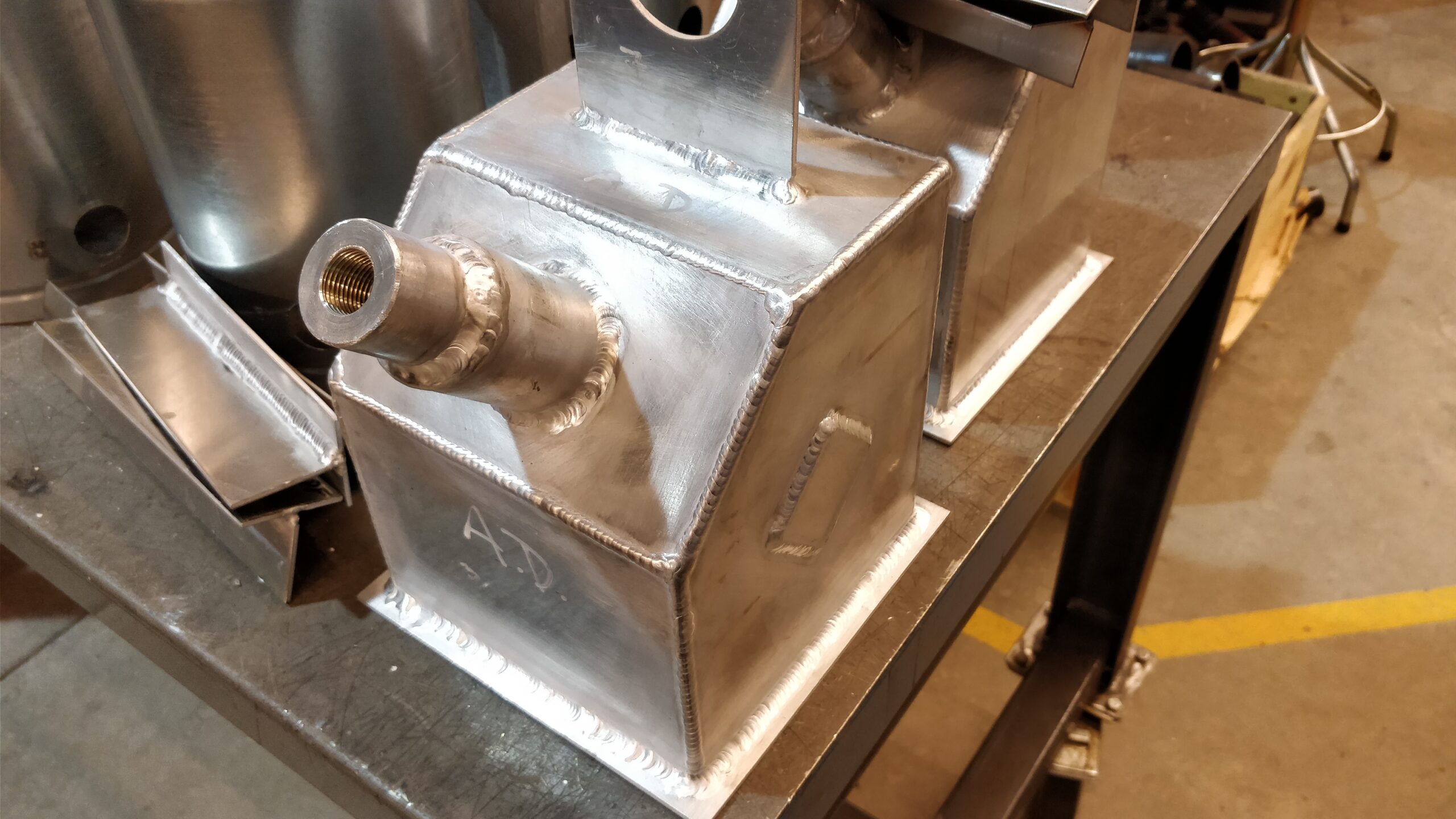

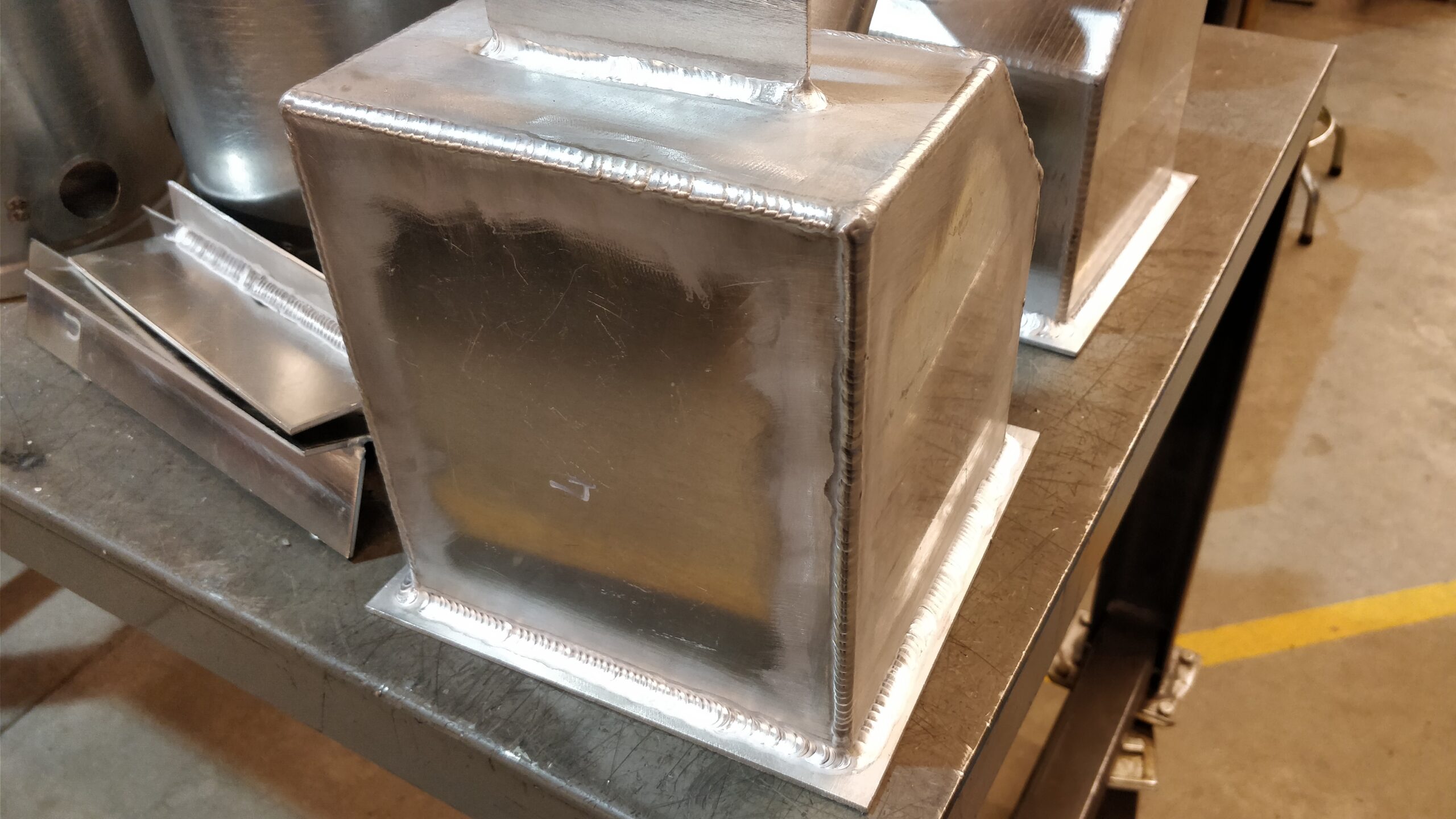

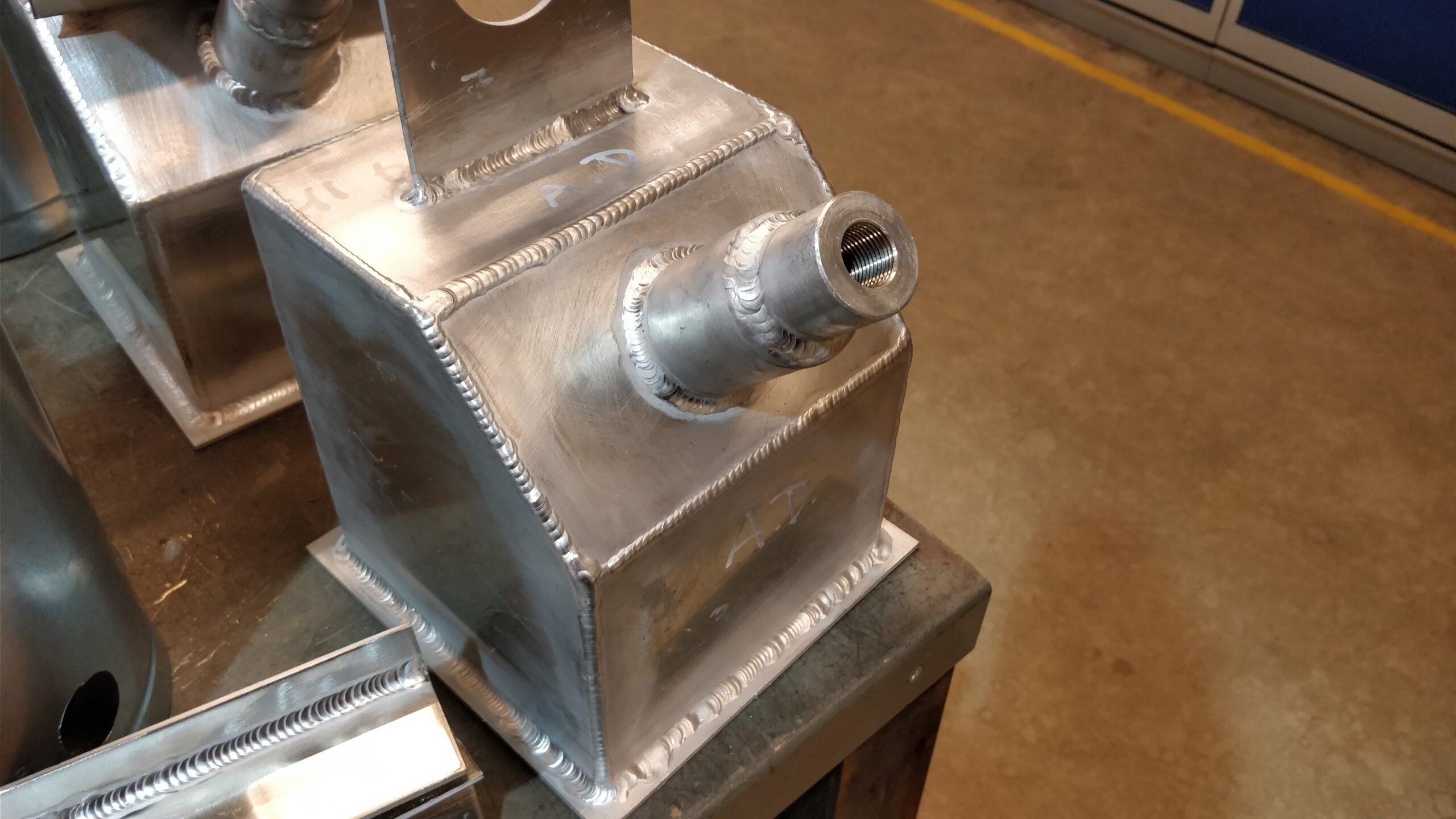

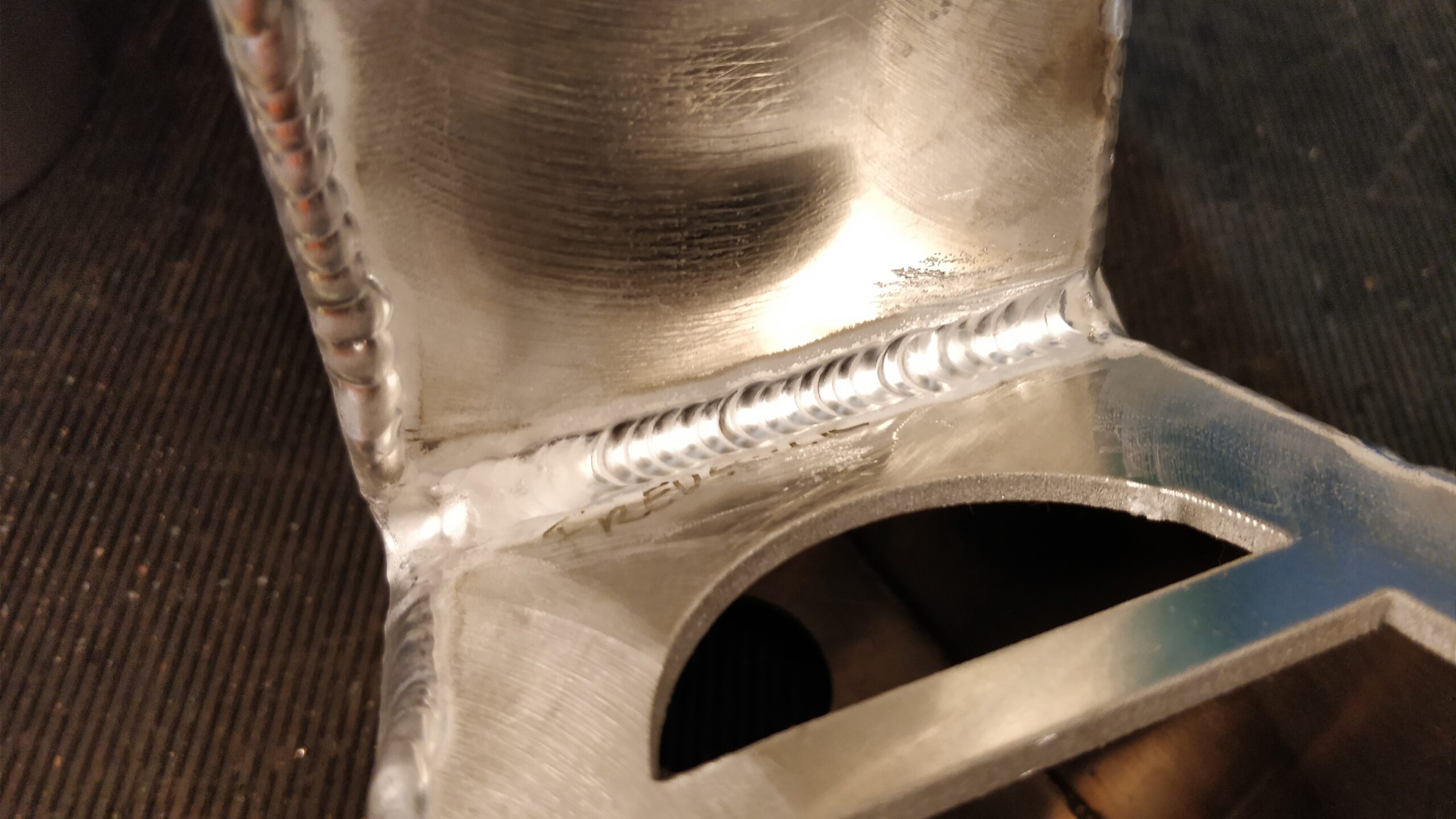

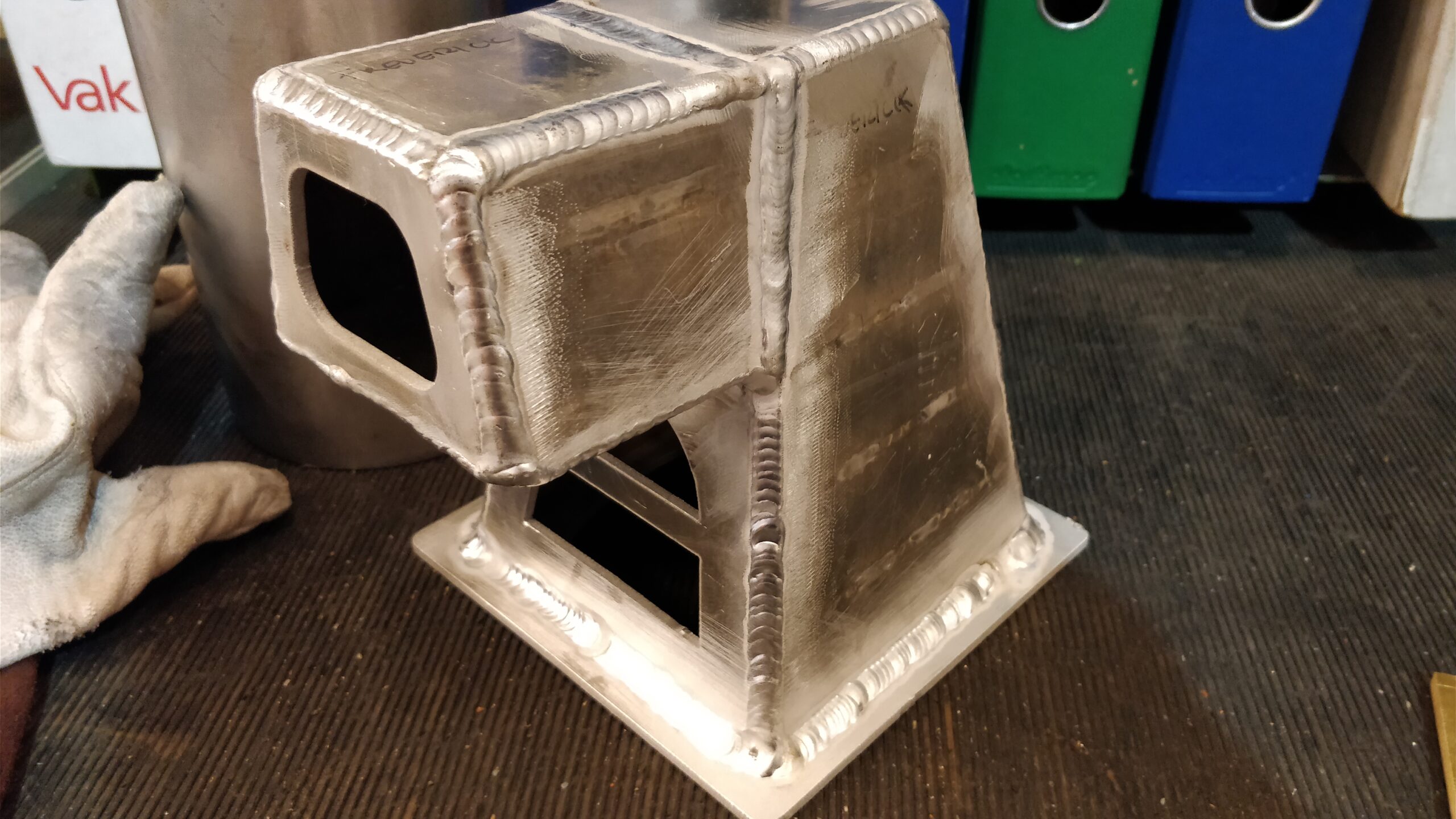

TIG 141 welding

One of the projects was creating a Christmas candle holder using simple geometries. Must admit, welding aluminum was both fun and challenging. Especially challenging it was when passing by a thin place. Managing the proper speed is an art in itself.

Another part for training with TIG

Test

One of the requirements of the test was welding in PB or PF positions.